Corona Treatment

Have you ever wondered why it is difficult to write or print on plastic – why the ink is smearing when you rub it? The reason is the relative energy between the two surfaces, and the only way to solve the problem is to modify the surface of the plastic and increase its adhesive capability. The process capable of this is called Corona treatment.

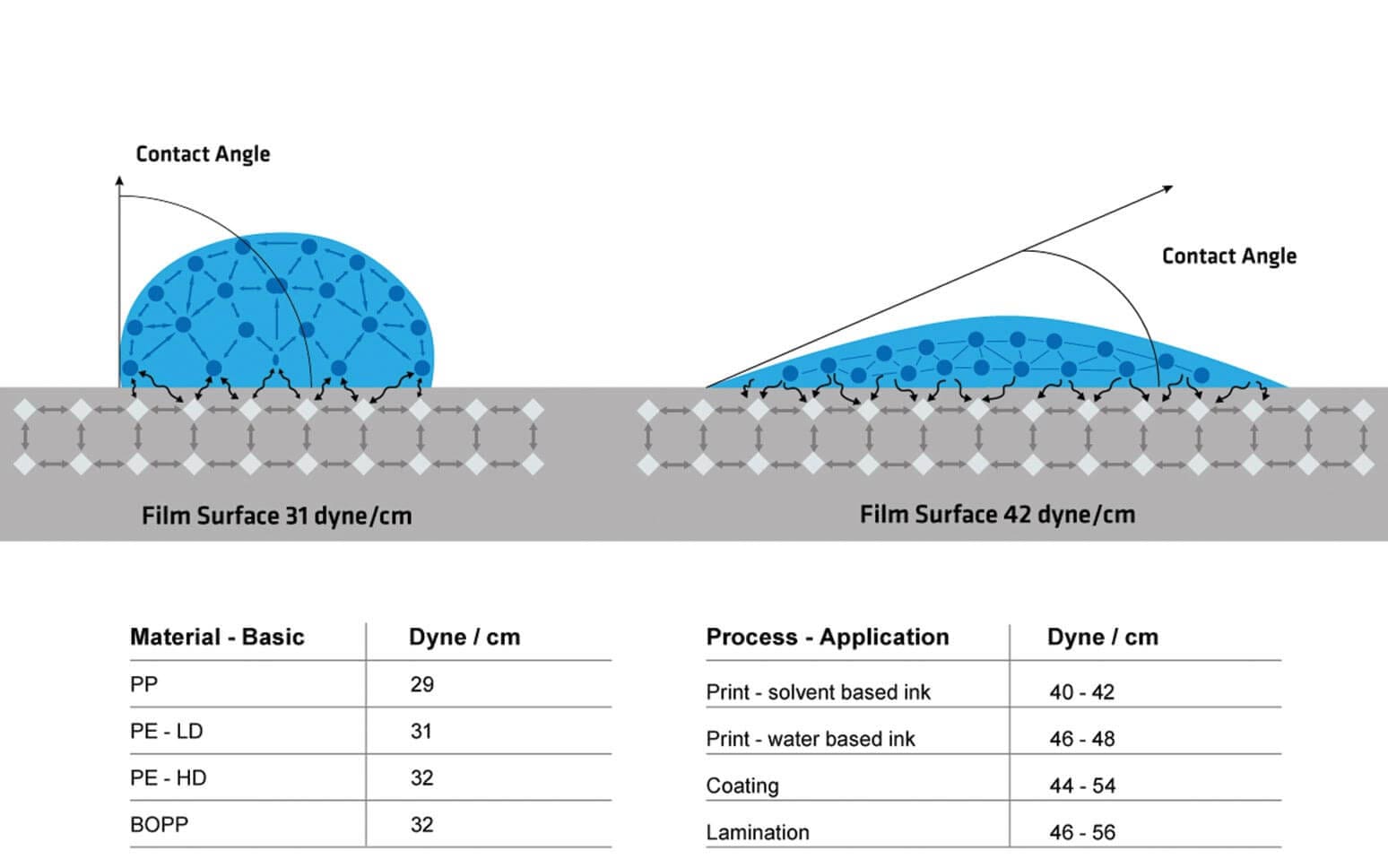

Whether a liquid wets a material well or poorly primarily depends on the chemical nature of both the liquid and the substrate. Wetting is the ratio between the surface energies of the liquid and the plastic material, and is measured in dyne/cm. Corona treatment ensures the surface energy of the plastic is higher than that of the liquid by increasing the adhesion of the plastic surface.

Surface energy with and without corona treatment

Left side: Low surface energy = high contact angle = poor adhesion

Right side: High surface energy = low contact angle = good adhesion

Being a man-made synthetic material, plastic consists of chains of molecules joined end to end to form even longer chains. These linked chains present few opportunities for bonding at the surface and need to be opened to increase wettability.

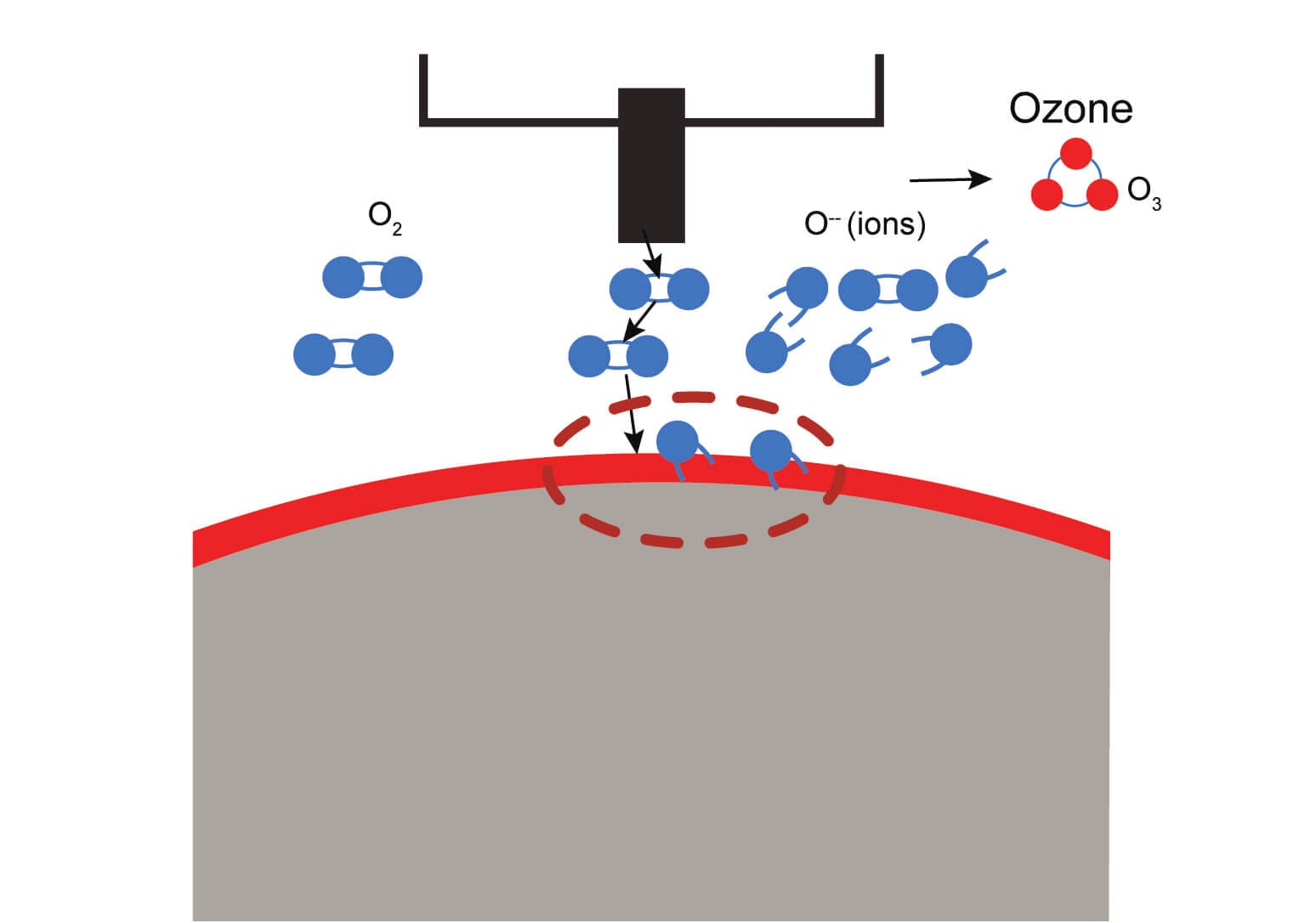

Directing a high frequency discharge at the plastic surface from close-range simply disrupts the molecules by oxidising it. The discharge splits the carbon molecules and breaks the oxygen into ions, some of which enter the surface layer of the plastic and improve the bonding, while others form into ozone that needs to be extracted.

The new carbonyl groups created have a higher surface energy, and this improves the chemical connectivity (dyne/cm) between the liquid and the plastic.

Corona treatment affects only the surface layer of the plastic, to a depth of 0.01 micron, and does not change its appearance or strength.

The corona changes

Determination of treatment level

The effectiveness of Corona treatment depends on the specific material being used, as different materials have different characteristics and different amounts of slip and additives – and will therefore behave in different ways. Even two rolls of supposedly the same material can behave differently; it all depends on their precise chemical composition.

There are no limits to the substrates that can be Corona treated, but the intensity of the treatment required will vary significantly according to their chemical make-up. The best way to determine the exact value is by testing a sample of the actual film that is being used for a specific application.

Durability

In general, the more slippery the substrate the faster the dyne level will fall, and this applies also to thicker and older substrates where the slip agents may have migrated to the surface after treatment. Substrates that are difficult to treat will also decay faster, and those with a very high slip factor may lose their adhesion as soon as 24 hours after Corona treatment. The solution is to re-treat before using.

Material which has not been treated at extrusion can be difficult to treat afterwards. It is therefore recommended to treat the film just after the extrusion process and subsequently use a refresher treatment just before the liquid or media is applied to the surface.

The secret is to test and test again – and if you are unsure or require advice or assistance, please contact us – we will always be pleased to help.

Get a Quote

Get a quote todayRelated Pages

Get a Quote

Get a non-binding quote for a Vetaphone Corona system or send us an e-mail: [email protected]

Get a quote today